The reliability of an automobile engine depends on the proper construction of the engine components. The constructional details depend on the stresses and the function of the elements.

In this article, you will learn that What is Cylinder Block or Engine Block? What is Cylinder Liner? And Types of Cylinder Liners.

Table of Contents

What is Cylinder Block?

All the major engine components are installed on or in the engine block. These components, including the cylinder bores, are machined very precisely. They must be thick enough to contain the pressure of the burning fuel mixture.

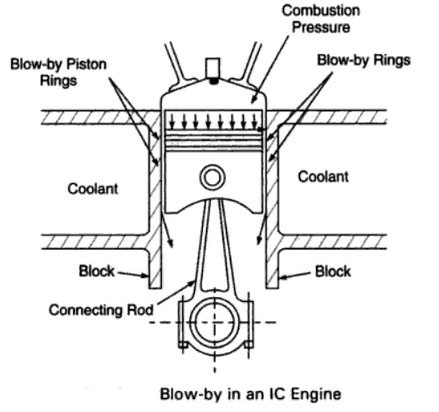

A tight fit must be ensured between the cylinder base and the piston rings to enable the piston rings to seal the combustible gas.

If the cylinder becomes oval due to wear some of the gas escapes through the piston rings.

The gas which leaks through the piston rings is called blow-by. Blow-by reduces the efficiency of an engine. The finishing on the cylinder walls also affects the ring seal.

The cylinder walls are machined to provide a very smooth finish. Special grinding stones produce small grooves in the cylinder walls, which collect oil.

These grooves help to lubricate the piston rings and piston skirts. Previously, most cylinder blocks were made of cast iron or grey iron as the material was easy to machine.

Aluminum pistons wear very well against cast iron cylinder walls. The main disadvantage of iron being is its weight, engine blocks are now being cast from lightweight aluminum.

An aluminum block weighs much less than a cast-iron block. An aluminum piston skin rubbing against an aluminum cylinder wall wears very quickly.

Most aluminum cylinder blocks are fitted with steel, or ductile iron cylinder bore liners.

What is Cylinder Liner?

The cylinder liner is a sleeve in which the piston of an engine reciprocates. The life of a cylinder between its re-bores depends on two main factors:

(i) Abrasion, and

(ii) Corrosion.

Abrasion depends on the atmospheric condition and the efficiency of the air filter and oil filter. Dusty atmospheric air is more harmful as it increases abrasion in the cylinder.

Corrosion of the cylinder is caused due to the corrosive products of combustion, which are formed after burning of fuel with air.

Corrosion is accelerated at low cylinder temperature due to acid bearing moisture on the cylinder walls. The use of separate barrels or sleeves, which are known as cylinder liners, provides a long life to the cylinder.

These cylinder liners are made of superior material and are fitted in the cylinder block. The liners are removable and can be replaced when worn or damaged.

The cylinder liner should have good wear resistance and the ability to retain oil to lubricate the surface between the walls and the piston rings.

Material for Cylinder Liner.

For cylinder liner, nickel-chromium iron has been popularly used.

The nickel-chromium iron used contains;

Carbon 3.5%;

Manganese 0.6%;

Phosphorous 1.5%;

Sulfur 0.05%;

Silicon 2%;

Nickel 2%; and

Chromium 0.7%.

To increase the wear resistance, the liners are hardened by heating to 855°C-865°C for 30 to 40 minutes and then quenched in oil.

By such heat treatment, the life of the liners is increased three times as compared with grey iron or cast iron cylinders.

Types of Cylinder Liner.

The cylinder liners or sleeves are of two types:

1. Dry liners.

2. Wet liners.

1. Dry Liners.

Dry liners are made in the shape of a barrel having a flange at the top. The flange keeps the liner in position in the cylinder block.

The liner fits accurately in the cylinder. The perfect contact of the liner with the cylinder block is necessary for the effective cooling of the liner.

Also, the gas pressure, piston thrust and impact loading during combustion are resisted by the combined thickness of the liner and the cylinder.

Therefore, dry liners are thinner, having wall thickness varying from 1.5 mm to 3 mm and are used mostly for reconditioning worn liners.

The dry liners are not in direct contact with cooling water.

2. Wet Liners.

A wet liner is so-called because the cooling water comes in contact with the liner. This liner is provided with a flange at the top, which fits into the groove made in the cylinder block.

To stop leakage of cooling water in the crankcase, the lower end of the wet liner is sealed with the help of sealing rings or packing rings.

As the wet liner has to withstand gas pressure, thrust and impact loading, the wall thickness of the liner is increased and is made more than that of the dry liner.

Generally, the wall thickness of the wet liner ranges from 3 mm to 6 mm. The outside of the liner is coated with aluminum so that it is protected from rust.

The wet liner is better cooled than the dry liner. It is easily removable when it is worn-out or damaged.

Comparison of Dry and Wet Liners.

1. A wet liner can be easily replaced whereas a dry liner requires special tools because it is tight-fitted in the cylinder block.

2. A wet liner is properly cooled as it comes in direct contact with the cooling water, whereas a dry liner does not come in direct contact with the cooling water. Hence, the working temperature of a dry liner is more than a wet liner.

3. A wet liner needs leak-proof joints so that the cooling water does not leak into the crankcase, whereas a dry liner has no such requirement.

4. A wet liner does not require accurate finishing on the outside, whereas a dry liner needs accurate finishing.

5. Finishing may be completed in a wet liner before assembly, whereas a dry liner needs finishing after assembly.

That’s all for the Cylinder Block or Engine Block and Cylinder Liner. I hope you like it. Please, don’t forget to share it.

Thanks!

what is steel material for liner?

Thank you guys so much