In this article, you will learn in details that what is an automobile transmission system, components of transmission system, and its requirements.

Table of Contents

What is Automobile Transmission System?

The internal combustion engine generates power which is transmitted to the road wheels.

The output from the engine is available in the form of rotation of the crankshaft. This rotary motion is transmitted to the road wheels.

The friction between the road and the surface of the wheel makes possible the movement of the automobile. Transmission system performs this function.

The automobile transmission system consists of several components. These components work together to transmit the rotary motion at the crankshaft smoothly and efficiently to the road wheels.

A sudden change of state, from rest to motion or vice versa is not desirable. It may be uncomfortable, or even dangerous, to the occupants of the automobile.

Therefore, the rotary motion of crankshaft should be transmitted gradually and not suddenly. Another aspect of transmission is that the motion from the crankshaft should not be transmitted as soon as the engine starts.

It is not desirable that as soon as the engine starts, the vehicle begins moving. The motion is required to be transmitted only ‘when desired.’

The rotary motion of the crankshaft gives rise to torque and transmission of this torque to road wheels give rise to a propulsive force or tractive effort causing the movement of wheels on the road.

When starting from rest, a great tractive effort is needed. The engine produces almost the same torque. This torque has to be enhanced so that enough tractive effort is produced.

This necessitates the introduction of `leverage’ between the engine and the road wheels.

A variation in the leverage is essential because if the same leverage is used for climbing as well as moving on the level road, the maximum possible speed would be unduly low.

Large leverage implies a large reduction in speed between the engine and the wheels, and at a quite moderate road, the engine speed would be very high.

But at high engine speeds, the engine torque falls off so that tractive effort available would be less thereby reducing the road speed.

On properly maintained road comfortable cruising speed for a car can be approximately 50 kilometers per hour, and with a wheel diameter of 30 cm, it will have a rotary speed of about 1060 rpm.

Considering the speed of the engine to be about 3500 rpm, the automobile transmission system will have to reduce 3500 rpm at the engine to about 1060 rpm at the wheel (ratio 3.3:1). This ratio may vary with the engine size and engine specifications.

While the nature of transmission is not affected greatly by the changes in the form of ‘carriage unit,’ so that the transmission of a 4-wheel driven vehicle is similar to that of rear-wheel driven vehicle, the arrangement of transmission will be different in both the cases.

The axis of the rear road wheels, where the motion is usually transmitted is perpendicular to the center line of the automobile.

Therefore, drive between the engine and the road wheels are turned through 90 degrees.

If the automobile moves on a circular path, the inner and outer wheels will traverse circles of different radii. Thus, the inner and outer wheels travel different distances.

Because the automobile moves as a single unit, they have to travel different distances during the same period.

In the majority of automobiles, the engines are fitted in the front portion on the frame of the carriage unit. Usually, the motion is transmitted to the road wheels on the rear side.

The distance between the two is quite considerable. The motion is required to be transmitted through this distance. Also, the rear axle is attached to the frame through springs.

Due to the uneven surface of the road, the axle moves up and down, and the springs flex. The relative positions of the engine and the axle changes and automobile transmission system should be capable of taking it up.

Watch the video for in depth comparison between Automatic Transmission and Manual Transmission.

Requirements of Transmission System.

The transmission system, therefore, should fulfill the following requirements:

1. Enable the engine to keep disconnected from the road wheels. These should be connected only ‘when desired.’

2. Enable the engine, when running, to be connected smoothly and gradually without jerk to the road wheels.

3. Enable the leverage between the engine and the road wheels. This leverage should be variable to cope with the different conditions such as starting from the rest, moving at uniform speed or climbing a hill.

4. Enable the reduction in the engine speed.

5. Turn the drive through 90 degrees.

6. It should enable the running of inner and outer road wheels at different speeds when the vehicle moves on a curved path.

7. It should provide the relative motion between the engine and the road wheels when they move up and down due to the uneven road surface.

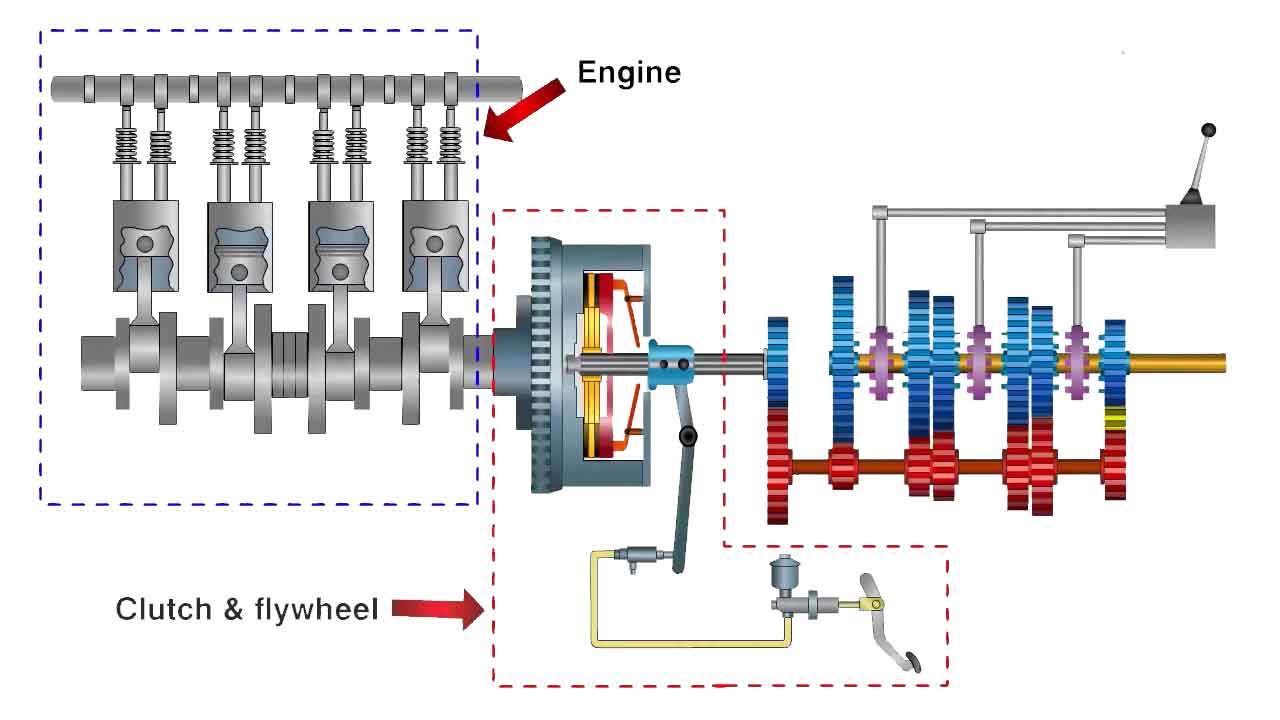

Components of Transmission System

The transmission system consists of the following components:

1. Clutch.

2. Gearbox.

3. Propeller shaft.

4. Differential.

5. Live Axle.

1. Clutch:

This component enables the engine to keep disconnected from road wheels.

The rotary motion available at the crankshaft is not transferred to road wheels. It allows the transfer of motion when desired by the driver of the automobile.

Clutch also allows the transfer of motion gradually so that the vehicle starts moving gradually. It works on the principle of friction.

2. Gearbox:

It consists of some pairs of gear wheels. These transmit the motion available from the crankshaft, through the clutch, at different speeds.

This provides required leverage between the engine and the road wheels. This leverage is variable to cope up the different conditions encountered during the movement of the vehicle.

3. Propeller shaft:

The third component of the automobile transmission system, which transfers motion from the gearbox end to the differential end. The distance between the two can be large, and therefore, it is a shaft which is thin and long to connect the two.

4. Differential:

One of the requirements of the transmission system is to turn the motion through 90 degrees as the axis of the propeller shaft and live axle are at a right angle to each other. This is performed by the differential through wheel and pinion arrangement.

Another function performed by the differential is the variation in the speeds of inner and outer wheels when the vehicle is taking a turn.

5. Live axle:

The axle where motion from the crankshaft of the engine is transferred is known as a live axle. The other axle takes up only the load of the vehicle and therefore is termed as dead axle or simply the axle.

The motion is generally transferred to the rear axle, but it can be transferred to the front axle or both the axles. When the motion is transferred to both the axles, it is known as four-wheel drive.

Finally, motion is transferred to the road wheels at the two ends of the live axle.

The wheels rotate, and friction between their surface and road surface makes possible the movements of the vehicle on the road.

That’s all for the automobile transmission and components of transmission system. I hope you like it. And please, don’t forget to share it. Thanks!

Hello, This blog is very useful !

Thanks for giving this amazing information.

Great, But is there a detailed notes on fuel, cooling, lubrication, and ignition systems?

Well done!!well done!!! It is well articulated.

I believe you have noted some very interesting points, appreciate it for the post. Berny Montgomery Morvin

Of course I have got it. I really appreciate it and also interesting thanks

Whoever created this blog may the good Lord bless him/her

I really appreciate it and its very intresting. I got it thanks

Try this if you need an electrician urgently in the event of a breakdown.